Modern free float rails are really slimming down. I have some concerns. I have really come full circle for my thought process on super skinny modular rails and my conclusions are not re-assuring. As AR accessories have progressed, we have moved towards ergonomics and modularity. We have lengthened free float rails and slimmed them down. Warfighters need room for grips, lights, and lasers so it’s understandable that shooters want the real estate. Well… What we have done is created a long, skinny, skeletonized beam and weighed it down at the end. Is this the formula for durability? Read on:

Enter the Ongoing URG-I Fiasco: AKA #Railgate

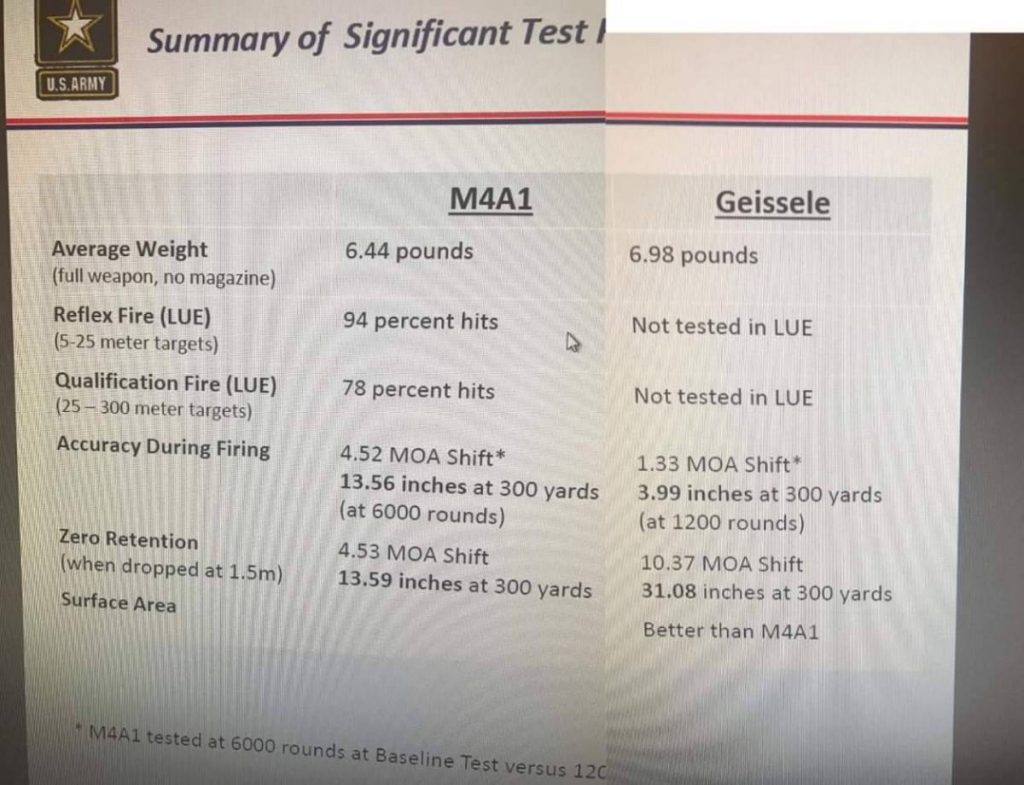

Take this with a grain of salt until we receive some more clarification from the military, but the following appeared on a Facebook URG-1 group page. A user posted a spliced PPT image from an unknown slide series which claims to show the Geissele rail suffering damage during drop testing:

“During testing the rail when dropped shifted 10+ moa while a m4 only saw 3 moa. Source is a pp presentation the army put together. Anybody have anything on this?” User MadMax 1611 – Geissele rail scuttlebutt Editor’s Note: Geissele has deleted the thread.

This army PPT presentation lacks context. We don’t know the specifics of the info, and perhaps it is illegitimate. As a result of the above slide and those very same questions, several Mk16 owners on AR15.com decided to put the issue to bed by performing their own very simple drop tests. The results?

Let’s take a look at a sample of some user posted photos after their own drop test:

Collage of damage to the rail – Original Images and additional images in thread: Geissele rail scuttlebutt Editor’s note: Geissele has deleted the thread.

The user revealed that the gas block made contact with the rail causing significant interior deformation and loss of MAWL zero with his drop test. The test was then repeated with a brand new rail and another user recording the test:

So we have several cases with the URG-1 deforming upon impact (with mawl attached) according to these users on AR15.com. In the above video, the gas block again contacted the inner rail and appears to cause some damage. Now would these rails fail without a MAWL? That’s what we don’t know. My bet is not. The added weight of these laser aiming devices no doubt play a role in the deformation as they simply add weight to the end of the beam and exacerbate the flexion upon impact. The MAWL weights 10oz by itself! So are modern thin and skinny free float rails durable enough to handle these devices?

Free Float or… Don’t?

Geissele is well-respected and makes “bombproof” products. Bill notes that the Mk16 was designed to meet the customer’s specifications. We have many rails from a variety of MFG’s that are outwardly similar to the Mk16 and feature plenty of MLOK slots on every facet. I think they would meet the same fate. I think the lesson is that longer, skinnier rails in general will be weaker than the thicker, shorter quad rails of the past. Case in point:

The M4 KAC RAS showed less deflection in the PPT slide. Why? I think its simply stronger by design. The KAC RAS attaches to the hand-guard cap and delta ring assembly. It is not free-floating. This means that the major support structures of the rail are the rail itself *AND* the barrel. Together they form a more durable structure than the Mk16. Can any free float rail compare to the strength of a quad rail assembly wrapped around a M4 SOCOM barrel? I am beginning to have my doubts.

Turns out the old warhorse KAC RAS still has some game in this day and age.

I have had these concerns for some time, but I didn’t have really enough data or examples to make a convincing argument. I began to write about my concerns in July with my DMR article. I noted that its relatively easy to twist and shift long skinny rails. With these issues rearing their head on the MK16, I think I have some additional examples to bolster my argument. Many other skinny rail designs could/will suffer the exact same fate when dropped. If your laser and BUIS are no longer able to hold zero due to impact then we would consider that rail a no-go. Minimal gas block clearance, long skinny beam with lights and lasers at the end… It’s a zero shift waiting to happen! These issues from impact are of concern enough, but think about this as well: the barrel whip of skinny barrels can also cause a rail to contact the gas block. This will be exacerbated by MID LENGTH gas systems. This may lead to inconsistent accuracy.

Long, skinny, skeletonized, and weak with very narrow clearance of the gas block does not a confidence inspire.

There are several failure scenarios with a skinny free float rail:

- Rail is bent: Loss of BUIS and IR device zero

- Rail is bent and in contact with gas block: Loss of BUIS, IR device, and Primary Optic zero.

- Rail is not bent, but barrel whip causes the gas block to make contact with the rail, resulting in inconsistent accuracy/ accuracy loss.

These scenarios weren’t a wide-spread issue with older free float systems. I have been here a long time. I first purchased an AR in 2002 and have been obsessed ever since. Go back a few years in your mind. Think about our old quad rails with lots of internal clearance, thick walls, and more weight. (Ugh, I don’t miss the weight!) Now flip over to the modern era where we are equipping longer, skinnier, narrower, skeletonized systems with very little clearance between the gas block and rail. Which one will tolerate impact better? I thought so too.

So how do we get around this? I have a few suggestions:

Solution 1: Choose a rail length which allows the gas block to remain exposed.

Aero Precision M5E1 with exposed gas block. Impacts short of a tank running over this system wont cause the rail and gas block to make contact. Gotta keep ’em separated. Hey HEeey wait. No. I’ll stop.

This is an obvious solution for the super slim rails. In addition to removing the tight clearance issues, the shorter rails will also be stiffer. The modern rails pushing 15 inches are less stiff than their 12, 9, 7 inch (etc) counterparts. It’s just leverage. The longer the rail, the more leverage the aluminum must resist to ensure it doesn’t bend. Shortening the rail and exposing the gas block stiffens the rail and ensures the gas block plays no part in damaging the interior of the rail.

I found the Aero Precision Atlas S-One to be super slim and ergonomic… in fact its my favorite rail… but the clearance is so tight below the supplied gas block that MLOK accessories contact the gas block when installed. I am likely going to order a shorter model that sits behind the gas block.

Not worried about impacts? What happens if you mount a bipod at the end of a 15 inch rail? Is the bipod load causing your rail or MLOK accessories to contact the gas block? There goes your primary optic’s zero as now your rail has applied pressure to your formerly “free floated” barrel. Some gas block and rail combos are so tight that hand pressure on the barrel can cause it to contact the rail!

What if you drop your rifle and the rail is now contacting the gas block? Bye bye primary optic zero. Bye bye BUIS zero as it’s now canted with the rail. This is not a good scenario.

Solution 2: Choose a rail with a larger I.D.

Though these rails can still shift on impact, if the clearance between the gas block and rail is large enough then it’s one variable that can be eliminated. Your BUIS may be tweaked, but your primary optic will remain un-affected. If you MUST hide your gas block under the rail, get a rail with more, and not less, clearance around the gas block.

Old school rails might not be high-speed… but good old quads may in fact be stronger than M-Lok simply due to the extra material of the picatinny rail. I don’t own the above rail anymore because it stopped being high speed! Don’t I feel dumb.

What’s my preferred setup? My preferred setup is a A frame front sight outside the rail. Still. Call me old-fashioned, but the damage to the rail wont throw off my front sight OR my optic.

Wrapping Up:

The impetus for writing this article is to air my concerns regarding super slim / super skinny rails. I believe my concerns to be valid for all skinny rail systems and we should be aware of rail length, gas block clearance, and be aware of the effect of heavy accessories at the end of a long rail. One drop and your gear is out of alignment. BUMMER.

From here, I hope our collective knowledge continues to improve. I hope I have opened some eyes regarding this recent trend towards modular, skinny, long free float rails. Sometimes its good to take a step back and examine equipment from outside the you-tube bubble. We buy this stuff for sport, but we recognize it can be used in emergencies as well. We hope we never have to worry about our optics losing zero in a life or death scenario… yet several thousand miles away there are individuals who depend on the strength of their equipment to stay in the fight. Our collective passion (and greenbacks spent!) for the black rifle has helped usher in an era of R&D unmatched by any other weapon in existence. As a community, we must also recognize that there are limitations and dead ends… even if those dead ends are popular and enthusiastically received.

As far as the Geissele Mk16, big G has promised to take care of any customers who are having an issue with the drop testing after the holidays. Good news that G takes care of customers.

Update 6/19: I have been observing the ongoing saga and it is necessary to note that Geissele has locked and deleted threads and blocked users who ask questions about the drop testing on platforms such as IG, Facebook, ar15.com, etc. I am sure the team will stand behind the rails warranty, but silencing critics and deleting questions is not a good showing.

Be aware, keep your rifle ready, your powder dry, and build them to be ready for anything.

Lothaen OUT!

On my original A2 I went with a Troy two piece free-floating MRF Quad Rail that clamps around the original barrel nut. It’s big and heavy, but tough enough to drive tent stakes with. After buying that I could never get into the skinny rails.

Matt

Very good article. I had wondered about the durability aspect watching 3 gunners train last summer with their modular skinny rail set ups. The article certainly answers that question. Don’t drop your gucci set up LOL.

I too have wondered about this. A basic education and understanding of physics and mechanics should make others wonder too. Ultralight weight and looking Ace at the range will not keep you alive.

Pick gear basic on reason and logic, not marketing and “keeping up with the Joneses”.

What free float handguard, other than the LaRue you posted a picture of, has a stout mounting system and is strong enough to not bend? Are we going back to quad rails, simply for the added metal?

I wouldnt go that far. A) shorter rails will be stiffer B) gas blocks in front of the rail will prevent issues as above.

A hard enough hit to any FF rail can tweak a buis or laser. Choose shorter and stiffer setups. Also keep your front sight on the barrel. I think thats the takeaway here.

KAC URX4

I think that there are points to both. But, I want to see a whole lot more data on that Army testing (not just one slide) before making a call against free-floating. I understand that there was civilian testing after the fact “to replicate”, but is there any more information specific to the Army’s testing methods?

That’s what I want to see.

The test wasn’t against free float rails, just the Mk16 in particular. I guess you could say it’s really a test on 13″ super skinny modular rails as they likely all have the same issue.

The MK8 G rail would probably be fine. They use a similar rail on the HK416 and M110a1. The groups were much better with G upper. 1.3 Moa compared to 4.5. I wonder how the DD RIS 14.5 compares to the G upper? The mid length gas system is a plus and the G upper uses a Daniel Defense barrel while the M4 probably has a Colt barrel. One upper had 6000 rounds and the other only 1200 so I don’t know how big of a difference that made.

I’m always afraid to expose too much of the gas tube. Free floats aren’t always a perfect fit against the back of the gas block. Any recommendation on max allowed length of the gas tube?

I am unsure how much is safe, but if a handguard exposes a little too much tube I instal the handguard cap behind the FSB to cover a bit more of the tube.

Would a material change be in order? Aluminum is strong for its weight but would a steel rail suffer the same issues absent things such as galvanic corrosion?

7075 aluminum has supposedly made a difference with other rails testes. That’s the rumor I hear. 🙂

I 100% agree with you.

I had (still have) a BCM Mid-length, 16inch BHF, A2 front sight with a Centurion Arms 9 inch FF quad rail on it and it is rock solid.

I was in the process of building another 16inch mid-length mid 2018 and was dead set on getting the BCM MCMR for that build. That was until one day out on a private shooting range a friend of mine stepped back and on to his BCM with a 13inch KMR Alpha….and dented the eFFF out of it. He hardly stepped on it and he is not a big guy.

I ended up getting a BCM BHF 16inch midlenght upper, A2 front sight with their 9inch QRF quad rail. It is ever so slimmer than my Centurion Arms rail and maybe an ounce less, but solid as a rock.

Just say NO to skinny rails…and jeans 🙂

Thanks for that input Larry! Wow thats a bit eye opening!

I don’t have a Centurion but I have a DD MK18 rail and it is built like a tank. I would like to see drop test on the DD MK18 vs the KAC M4 RAS. It is also free floated and the KAC RAS isn’t.

I have no doubt there has been some issues, but BCM, DD, Knights, Centurion, G, etc…etc…etc, have sold THOUSANDS of these uppers with skinny MLOK rails on them by now. If there were major issues then it would be everywhere.

I personally have a MCMR from BCM on a 14.5 middy upper. Zero issues. I only have a front sight (DD), surefire scout with RM45 mount (on the top rail) Ariska MLOK indexer and the BCM QD MLOK mount. The two MLOK attachments are not near the gas block and have plenty of room. If the barrel is whipping so hard to touch those nuts I would not want it. I can see the nuts and the gas block….zero scratches after thousands of rounds.

I have Quad uppers as well, the BCM QRF on on upper, Centurion Arms on another. Yes I think they would be harder to jack up/dent, break if I used them as a club. The MCMR is not fragile at all. I throw it up against a VTAC shooting boards or various barriers during drills and I only have the BCM MLOK rail covers which are super slim. Those same rail covers allow me to shoot a lot without needing gloves. My front hand is not over the gas block though.

I carried a rifle in the Army. Weight is everything. Let me say that again, weight is EVERYTHING if you are out in the field carrying a rifle. My MCMR with its ELW barrel is so much easier to carry than my heavier quad rifles that would be better clubs than my MCMR. If you had to bug out on foot and were bringing a rifle, plus whatever else (pack loaded down) you would want to have the lightest rifle that is still combat effective that you could grab.

The military is using the Geissele MK16 rail so we don’t know if this drop test referenced is accurate. They are not using the 10.3 but they have issued the 14.5.

Or simply get an LMT monolithic upper that’s stronger than any rail out there. No zero shift and you get to keep a skinny MLOK rail if you desire.

I think this is where the Aero enhanced uppers and their rails really shine. I haven’t seen a more robust mounting system, and the enhanced rails are about as wide as standard quads if you mount rails to the mlok/keymod (designed to shroud some suppressors).

I think that the ALG barrel nut system is probably less prone to deflection and rotating than Geissele, but no data on that — but if ALG rotates it could damage gas tube… BCM’s nut is similar to Geissele, but shorter so potentially greater deflection there since less supported.

For free float rails, I’d think anything mounting on the standard barrel nut (or similar length proprietary) longer than carbine length is a mistake, which appears to cover the new LaRue.

Insofar as rigidity, a full length top pictatinny should do most of what you need insofar as rigidity w/ front gas block beneath without requiring full side and lower rails — yes, clearance matters and there should be some flex in favor of breakage. I suppose it’s a bit of discussion like fully enclosed vs C frames on automobiles…

But personally, I really like the Vltor clamp on gas blocks secured w/ rocksett for increased accuracy reasons on precision barrels. They’re A LOT stronger than you’d think, but I still like them beneath the rail. The PRI’s in the SPR have been known to be damaged and rotate, and those are outside the rail, so a risk either way.

Also, a separate issue, but I like to run an AFG w/ the GoGun gas pedal on support hand thumb for most of my semi-auto rifles and self-defense shotguns. The narrow handguards aren’t tall enough for the 90* side of the rail to align with the thumb — they’re more conducive to C clamp grips. The Fab PTK (their afg) usually comes with the VTS, which is a side rail thumb rest and a similar setup. IMO, provides a consistent support hand grip across guns, and works on piston guns with hot handguards without going the vertical foregrip route which is far from desirable.

Lol i’m not surprised by these findings. I still firmly believe that the problem are negative space attachment systems. They didn’t work when they first came out and they won’t work now. The best thing to do is to come up with a pic/mlok combo and space them out just like they do with existing mlok rails, like the f4 adaptive rail; the best of both worlds. And if you’re worried about scraping up your girly hands on the “cheese grater(such a bullshit argument),” you can put those nice little rail covers that’ll work with either pic or mlok attachment slots. Whatever your solution people just need to realize that picatinny isn’t going anywhere and probably won’t for a very, very long time.

Correct me if I’m wrong but skinny rail or not, isn’t the clearance between the gas block and the inner top of any rail going to be the same? All rails are flush with the top of the receiver, therefor the gas block is going to be in the same location to the rail in relation to where the barrel is extended from the receiver, no matter what the design. Seems free float no matter what design (I can see where the shorter the stiffer the rail) would have the same problem.

Then why does the inner diameter of rails vary from one to the other? I get what you’re saying, but I’ve had some rails that I had to use a super low profile GB to even get the rail on. My Centurion CMR and Monty’s MLOK were like that. Skinny to the point I needed to use a Centurion Arms gas block to get the rail over the barrel/GB assembly. I’ll say that while I ran a few of his rails, i never had an POA/POI issue even when they were dropped. And they were dropped. My LaRue rails did not require a super low profile GB so without going all Bill Nye the Science Guy on you I believe that indicates the I.D. varies from one manufacturer’s model to another manufacturer.

This is an older post, but still an excellent read…

So I jumped on the MLok rail and even the skinny rail bus for a time. I’ve always been a quad rail kind of builder and shooter what I was used to. Being a Texan, of course I was partial to Texan made products, but LaRue rails were one of the best IMO. I tried Centurion Arms, SLR, KAC URX 4, Troy, MI, JLBillet and finally LaRue’s newer MLok rails. One turn off from some of those rails were the fact they were 2 piece rails. While I personally didn’t have a 2 piece rail fail, one of my bro’s saw a 2 piece rail break first hand over in the sandbox. I think they do introduce a potential failure point that one-piece rails do not have. I also figured out that while I did learn how to mount an MLok attachment fairly quickly, that it was entirely possible to have a locking nut get caught at a 45 degree angle so that it’s crossing the slot at an angle, and then see that locking nut work its way through the slot. Not completely, but it was definitely jammed in the slot on its way out, and also made the mounted device asymmetrical to the rail. Besides all that, I’m just not in the camp that an MLok attachment is stronger than a picatinny attachment. There are some benefits though to the MLok, your mounts are lower profile which means the device, light or whatever will be tighter in to the surface of the rail. However, I felt restricted with the mounting surface that I didn’t with a quad rail. Specifically on some rails, the MLok slots give way to larger oval cuts to facilitate better cooling properties. Well with a quad rail you can have those cooling slots and still not lose one iota of potential rail space. Just to make one last comment – I’m not that guy with 25 attachments hanging off my weapon. At most I have 4. Front BUIS, a hand stop or fore-grip, a weapon mounted light, and DBAL/PEQ. That’s the most of any rifle I have. Short of some day getting a PVS-30 some day when i become independently wealthy, it will should never be more than four. I also noticed that the Cost of Ownership is higher with an MLok rail. MLok mounts seem to cost more, not to mention getting decent rail covers. Whereas with my LaRue quad rails, I can use the gazillion LaRue index clips I have. Cheap and more comfortable and effective than a skinny MLok with some Magpul Type 2’s or way overpriced covers (thinking Rail scales), which brings me to my last point. Even with gloves on I’ve gotten the hot hand. Especially after running some high round count drills consecutively, where I’m expending 700-1000 rounds in a very short time. Honestly, I’m not sure how big if a deal that was, it wasn’t like I could fry an egg on the rail, but no doubt if I didn’t have some decent leather gloves on my hands would have been might toasty.

So I went full circle and got to the point where i preferred a quad rail, specifically a LaRue quad rail, over the other MLok rails I had either built and used for myself, or built for others and got good hands on through thorough testing. There are some other really solid quad rail options out there. DD makes a fine quad rail as does Troy (one piece) and as much as I dislike them, the RAS was GTG as well. Everyone these days seems to be more interested in having a “sleeker, lighter, race gun”, but for me and my build SOP which says, “I will only build a weapon that I would deploy with” means I’m going to continue to stay old school and rock my quads. Quad rails that is.

The DD Mk18 rail seems super solid and I would put it against the KAC RAS any day. I’m sure they conducted drop tests on it. The Geissele Mk4 and Mk8 rails are probably more durable than the Mk16. The KAC free float on the MK12 is also super solid and I have no doubt it could survive the drop test. The G rail on the HK M110a1 is also the old style G rail and I have heard no problems with that. Not to mention the G rail on the HK416, it’s not super skinny and is much like the MK8 G rail. If they would of went with the MK8 G rail I bet they wouldn’t be having any of these problems. I don’t see what the problem was with that rail, they should of just used that for the URG upper. It is more like a traditional quad rail but with MLOK slots instead of Pic slots, It’s also thicker and more sturdy. The 10.3 version of the MK16 rail is probably fine but I bet the MK8 is even more sturdy.

I think the best bet would be a DD quad rail with the 14.5 inch mid length gas system using a FSB instead of a low pro gas block. That way they could get the benefit of the longer gas system and would still have a 9 inch rail for mounting accessories.

I’m sure drop test were conducted on the HK416 and HKM110a1. Both of those platforms have G rails. They are not super skinny but are like the MK8 G rail. If they would have went with the MK8 Geissele rail they wouldn’t be having these problems. It was fine for the 416 and M110a1 I don’t know why they weren’t happy with it and asked Geissele to design a new rail that isn’t as strong.

The 14.5 inch mid length carbine was a great idea and If they would have used the MK8 rail they would have a great new upper.

It’s now 2021, and skinny m-lok rail systems like this are now de-rigor and everywhere. BCM reports rifles with them outsell those without 10/1, so much so that they seldom produce/offer other versions.

The rails, regardless of manufacturer, can and sometimes do shift, especially on impact with barriers, concrete, falls, etc.